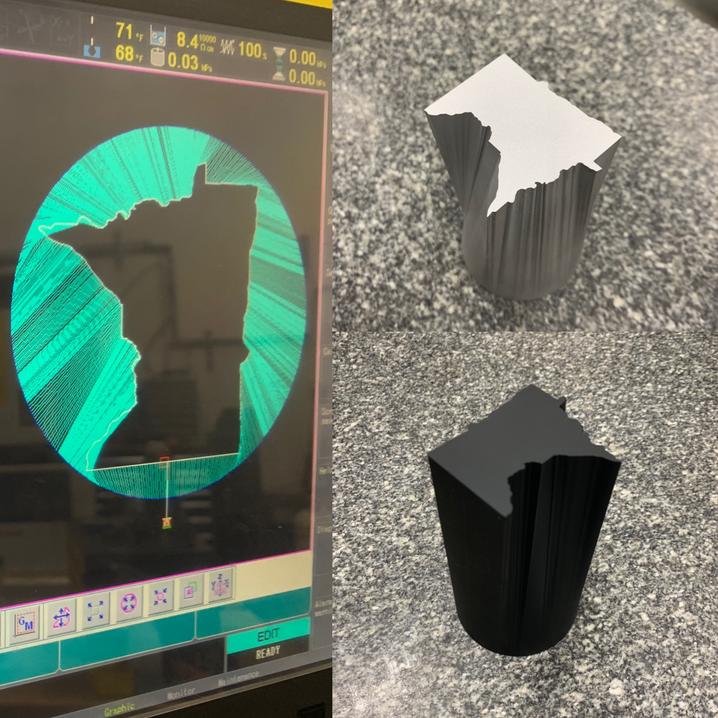

Wire EDM Services

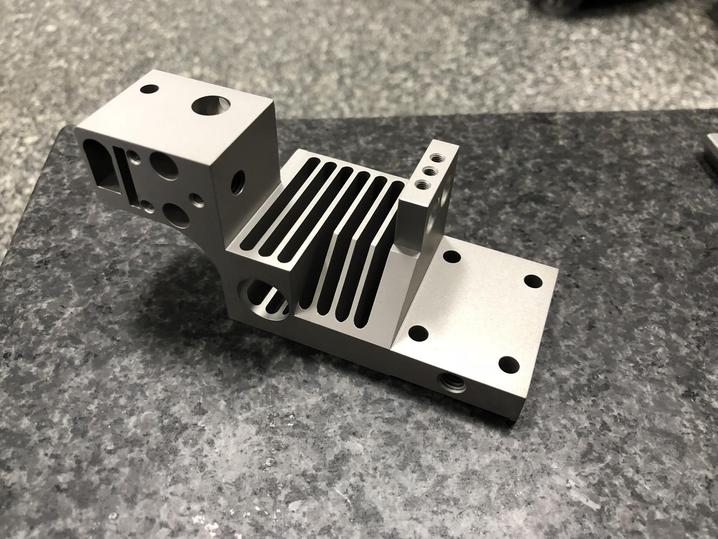

Our ever-expanding wire edm (electric discharge machining) department provides us with the ability to produce highly accurate parts, frequently working within .0001”. This non-contact machining method enables delicate features to be produced without the forces necessary for traditional machining. Equipped with high-precision hardware and fixturing, we are able to adapt to the complex requirements needed by our customers in the evolving manufacturing landscape.

PRECISION

Accurately machine materials too hard for traditional machining methods (tungsten carbide, hardened tool steel, hardened stainless steel)

CAPACITY

16” vertical travel allows precise features to be added to even the thickest parts

CAPABILITY

Programmable Robocut CCR rotary, capable of highly accurate indexing, turn-and-burn, and turn-while-burning operations

DELICACY

Using wire as a tool allows thin ribs, small holes, channels, and more to be machined through far thicker material than any mill is capable of

Protofab Engineering Qualifications

ISO 9001:2015 certified

DDTC Registered

ITAR Compliant

JCP Registered

Sam.gov Registered